PLASTIC INJECTION MOLDING

VIPOL specializes in injection, insert, and over-molding of a wide range of plastics, as well as being experts in working with elastomer resins. Our advanced capabilities and in-depth industry knowledge allows us to work as a single source solution for their manufacturing needs. From prototypes to high volume production, our state of the art equipment and facility gives us the flexibility to deliver precision molded products with rapid turnaround times.

3D PRINTING AND PROTOTYPING

Using a technology called 3D printing, VIPOL can turn your designs into reality. Just send us your design data for a quotation and when you are ready to order we will 3D print it and ship it to you – it is as simple as that.

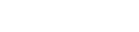

AUTOMOTIVE PLASTIC PARTS

Plastic parts and components are known to reduce costs and boost efficiencies in many industries – but nowhere are the advantages of plastics more evident than in the automotive industry. Plastics offer increased fuel efficiency, improved corrosion resistance, greater design flexibility, superior durability, higher performance and lower costs. .

Automotive manufacturing witnesses the highest deployment of robotic automation. Welding, assembly, machine tending, material removal, part transfer etc. are the assembly operations best suited to robotic automation. However, when it comes to tasks that need judgement and decision making, there is still scope for improvement in the performance of robots.

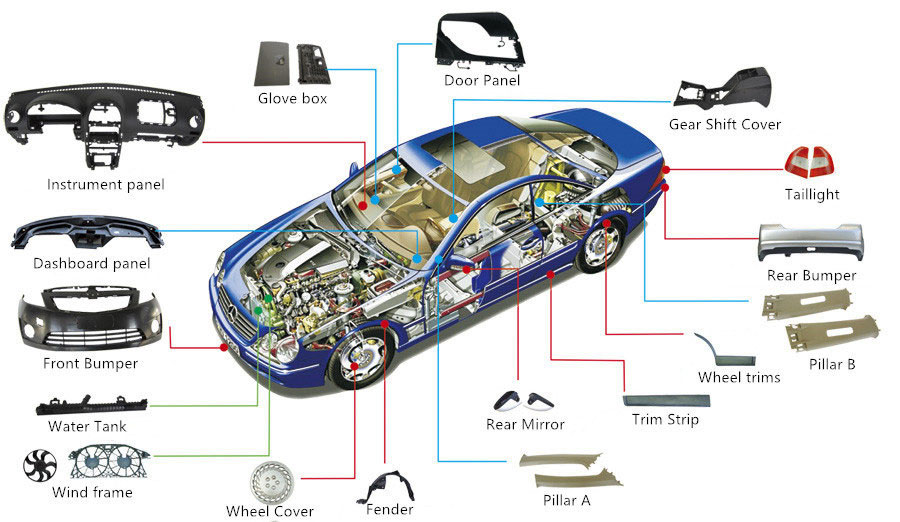

BATTERIES AND CHARGING SYSTEM

Vipol helps improve the performance of electric vehicles and industrial machines through industrial battery charger design and superior charging performance. The company contributes to the business success of its OEM customers through manufacturing quality and scale, and on-time delivery.

Direct materials are those which can be easily be measured and traced to the manufacture of a product. Since these costs are quantifiable based on the product, they have a direct effect on the production cost and therefore on the final cost of the finished good.A piece of furniture, for example, can be constructed from measurable amounts of timber, padding, and fabric covers – so these materials are considered to be direct materials. In a shoe manufacturing company, leather and cotton are also counted as direct materials..

INDIRECT MATERIALS

Indirect materials are defined as materials used in manufacturing processes that cannot be traced to an individual product or job. These materials, while consumed as part of the production process, are usually used in small amounts on a per-product basis and purchased in mass quantities.